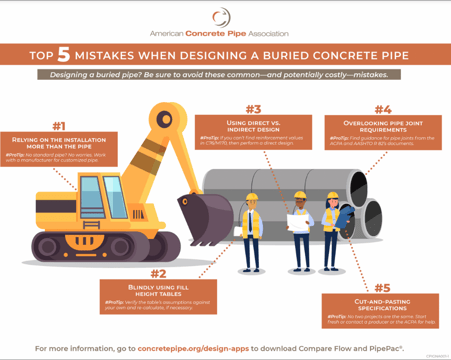

Top 5 Mistakes When Designing a Buried Pipe

June 5, 2020

By Josh Beakley, P.E., ACPA Vice President of Engineering

Designing a buried pipe? Be sure to avoid these common—and potentially costly—mistakes

The design of buried pipe encompasses many of the basic civil engineering concepts we learned in college: hydraulics, soils engineering, and structural engineering. Yet I’m willing to bet most of us didn’t take a class specifically dealing with the design of buried pipe. Thus, it’s easy to miss some of the finer nuances when designing buried pipe. Here are some areas where we have seen issues throughout our years in the industry. (Check out our infographic on the Top 5 Mistakes When Designing Buried Pipe.)

1. Relying on the installation more than the pipe

Pipe gets built in the manufacturing plant in a controlled environment, whereas the installation surrounding the pipe gets built in whatever Mother Nature provides. So, when the going gets tough, why ask the contractor to produce miracles? (Remember the saying, “it is not nice to fool with Mother Nature.”) The pipe producer can typically build a product to accommodate the environment.

#ProTip – Just because you can’t find a standard class of pipe, doesn’t mean our manufacturers cannot make what you need. Contact a manufacturer near your location to discuss your options.

2. Blindly using fill height tables

It sure is easy to look up what you need in a reference/fill height table, isn’t it? No calculations involved! But somewhere along the way, calculations were performed to develop those fill height tables. Do you know what assumptions were made in those calculations? Do they match your site conditions?

#ProTip – Take a moment to review what assumptions were made and see if they match your site conditions. If the assumptions and your reality don’t align, it’s worth your time to calculate the correct value.

3. Using direct vs. indirect design

Of course, you can calculate the stress and/or strain in the pipe based upon a particular soil-structure model for the pipe and its installed condition, and then specify the required properties of the pipe based on your direct design. Or, you could determine the load on the pipe, utilize a simplified relationship between the installed condition and a test condition in the plant, and employ an indirect design method to establish proof of performance of the pipe. Both methods have their uses.

#ProTip – Generally speaking, if you can find reinforcement requirements for the pipe in the tables of ASTM C76/AASHTO M170, Standard Specification for Reinforced Concrete Culvert, Storm Drain, and Sewer Pipe, then the indirect design method is your best bet. If you can’t find reinforcement values in C76/M170, then you’ll be performing a direct design.

4. Overlooking pipe joint requirements

So, you’ve determined the pipe strength that’s needed and specified the appropriate strength or class of pipe along with the appropriate manufacturing and installation standards. All done, right? What about the pipe joints? Most pipe standards don’t address the pipe joints. Pipe joints tend to have their own standards, and you’ll need to make sure you specified the appropriate one along with the pipe manufacturing standard itself.

#ProTip – Guidance on concrete pipe joints can be found in the ACPA Key Issue Statement, “Concrete Pipe Joints: Your Best Choice.” For non-industry specific guidance on joints, a good reference is AASHTO R 82, Pipe Joint Selection for Highway Culvert and Storm Drains.

5. Cut-and-pasting specifications

You worked on a pipe project last year, and now here you are again with another project involving buried pipe. To save time you may think, “Why not just cut-and-paste what I used last time and move on?” However, even when two projects seem similar, no two projects are ever quite the same. It’s always best to start fresh and consider the opportunities of each buried pipe project rather than make assumptions.

#ProTip – Consider the items above as a good start every time you begin a buried pipe project. How deep is the pipe? What are the loads, and what are the properties of the soil that will be surrounding the pipe? Is a special/direct design warranted? What type of joint is required of the pipe for the effluent running through it, as well as the external hydrostatic pressures around it?

To help specifying engineers avoid these and other common design mistakes, ACPA serves as the industry’s resource. Let us help you design your project! Our on-staff engineers are ready to assist, and our website is packed with information and materials for download.

Try our Free Resources

The ACPA has created and supports two different digital apps, Compare Flow and PipePac®, that help engineers determine the best, most efficient options for storm sewer functions. Both of these apps are free with Compare Flow being available on your smart phone’s app store and PipePac available online.

Webinar Available

Want to learn more about the design of the installation of concrete pipe? Check out our webinar where we review ACPA’s design apps Compare Flow and PipePac®.