1. Concrete Mix Designs

Once, there was only one kind of concrete mix: local aggregates, water, and portland cement. Today, alternative ingredients (typically chemical admixtures and/or supplementary cementitious materials) allow highly-customizable and versatile concrete mix designs that can provide a variety of benefits for concrete pipe such as improved production rate, safety, sustainability, aesthetics, product cost, and service life. Accelerators, air-entraining admixtures, permeability reducers, superplasticizers and water reducers are just a few of the many admixtures on the market today.

2. Reinforcement

Reinforcement improves the tensile strength of concrete, including that used for concrete pipe. Through the years, the quality and performance of reinforced concrete pipe has improved as a result of many research efforts, technological developments and updates to standards for concrete pipe and box culverts. In addition to performance benefits, some developments associated with reinforcement have led to optimized steel areas, reducing material costs.

3. Joints

Evolution of joint configurations—particularly advancements taking place within the last 30 years—has resulted in a variety of joint options and new gasket designs. These advancements also represent an enormous improvement in quality control, which has benefited both the installer and end user. Recent concrete joint designs provide enhanced performance characteristics with respect to resistance to infiltration of groundwater and backfill material, resistance to the exfiltration of sewage or stormwater, ability to accommodate lateral or longitudinal movement, continuity, and smooth flow line, and ease of installation. Contemporary joint categories include flexible sealant joints, O-ring rubber gasket joints, offset joints, pre-lubed gaskets, and rubber gasket joints for shaped concrete pipes and structures.

4.Production, Quality, and Standards

In the early 1900s, the demand for the precast pipe was mainly for rural land drainage applications. In recent years, the demand and applications of precast products have increased tremendously, and the precast concrete pipe industry has been keeping up with this increased demand through innovative production methods. For example, the pipe is now available in many shapes and sizes. Plants have been automated, allowing the industry to respond to the increased demand, while at the same time, increasing the quality, speed, and safety of production. Furthermore, quality control processes have been added at each production stage. Finally, over the years many industry standards, as well as design tools and programs, have been developed.

Hundreds of individual concrete pipe manufacturers are responsible for the incremental product improvements that have taken place over the years. While they are always competing amongst themselves to find “the next best thing,” these manufacturers are also governed by stringent standards. This means only well-researched, thoroughly proven advancements are adopted–a situation that eliminates nearly all risks to end users and the general public.

Want to Learn More about Innovation in RCP?

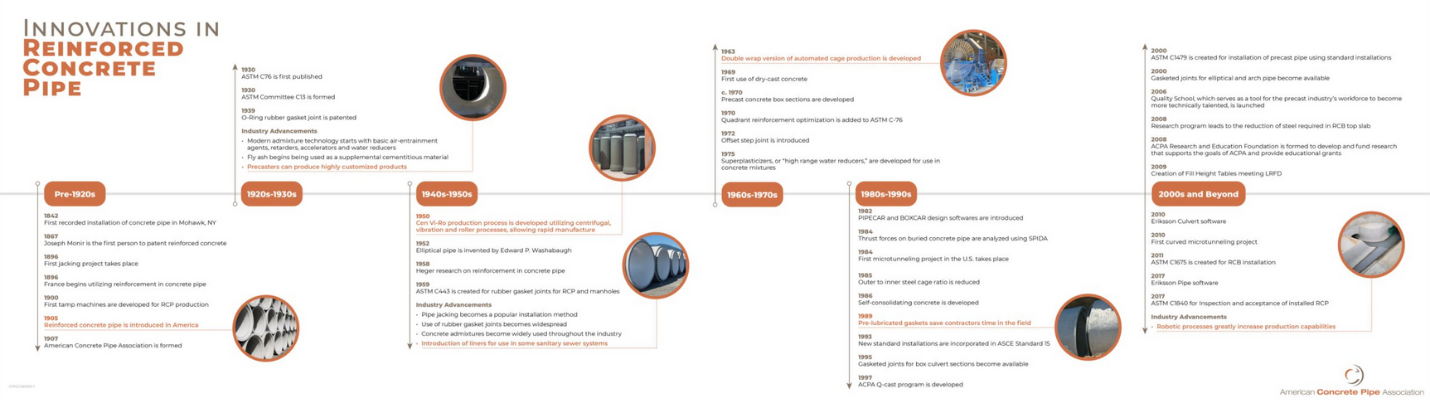

Check out our Innovations in Reinforced Concrete Pipe infographic available as PDF or as an image and watch our webinar Innovations in RCP Infrastructure.

What is Innovation?

People have an intuitive appreciation for innovation—throughout history, innovations have repeatedly solved pressing problems. When we think of innovation, however, we often conflate it with invention or breakthrough moments when something entirely new is conceptualized. But there are other, equally critical, types of innovation: upgrades to products and gradual optimizations over time.

Each of these three categories—invention, upgrade, and optimization—contains a significant potential upside, but also carries its own degree of risk. Generally speaking, there is a direct relationship between upside and risk. While inventions often include the highest potential upside, they also include the highest risk. That is, there may be enormous unforeseen downsides.

For example, a commonly known innovation-gone-wrong is the Boeing 737 Max 8. This new and inventive aircraft design utilized a larger engine that would allow for fuel savings while also maintaining the same functioning design to permit minimal pilot training prior to operation. While the intention of the new design was to create economic efficiencies, the race for profit led to many oversights in safety and resulted in an irresponsible advancement. The repercussions of Boeing’s innovation were fatal and resulted in the death of nearly 350 people.

A lower-risk form of progress is optimization. In this category of innovation, micro-enhancements result in steady improvement over time. For situations that don’t tolerate a high degree of risk-taking, such as infrastructure projects, optimized innovations that occur over time often offer the best approach. Such innovations result in a highly functional product, without the excessive potential for expensive or dangerous unforeseen consequences.