Debunking Misconceptions About Concrete Pipe Performance

By Josh Beakley, P.E., ACPA Vice President of Engineering

Concrete pipe and concrete pipe joints are among the most durable, resilient infrastructure materials on the planet. While reinforced concrete pipe offers proven performance, the ACPA occasionally encounters misinformation about its products’ longevity and durability. Here, we address three misconceptions surrounding concrete pipe performance — joint performance, porosity, and gas permeability – to debunk some popular myths and provide resources for further information.

Joints

Are concrete pipe joints sound? When properly specified and installed, the answer is a resounding yes. In our experience, issues with concrete pipe joints typically arise from two scenarios:

- improper specification of the pipe joints, particularly for sanitary sewers; or

- older pipes that have not been installed to today’s standards, which have continually improved.

Concrete pipe offers the design engineer several different joint types, depending on the application, to meet the utmost demanding project specifications. Because of its superior durability, strength and joint system performance, con

crete pipe remains the pipe of choice for engineers and owners of drainage and sanitary sewer projects.

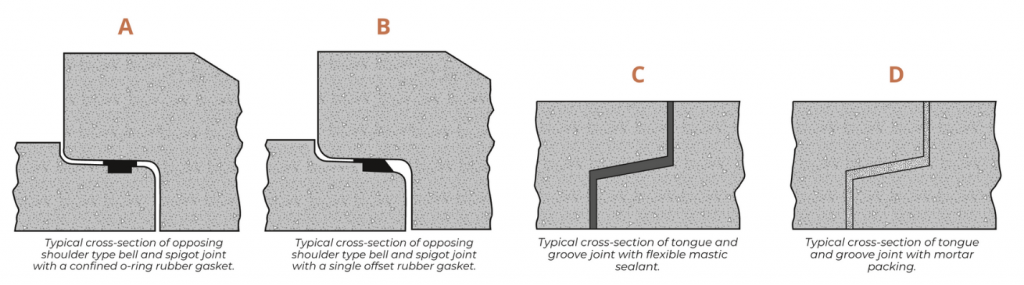

Concrete pipe joints can be designed to meet different sealing requirements, with the ability to accommodate lateral or longitudinal movement by using several joint options, including: mortar, flexible joint sealants, rubber gaskets, and external sealing bands. For more on the performance of concrete pipe joints, see our resource Concrete Pipe Joints: Your Best Choice.