Controlling Stormwater Discharge into Wetlands

The precast concrete box system controls stormwater and extends surface parking.

When a mixed-use development needed a solution to control stormwater runoff, a system of reinforced precast concrete box culverts provided the answer. Located south of Ann Arbor in Pittsfield Township, Michigan, the development included multiple buildings on a site containing regulated wetlands.

The wetlands on the 15-acre site serve as a buffer between existing neighborhoods and the development, which includes 84 apartment units in three buildings, 94 rowhome units in 11 buildings, two mixed-use commercial buildings, a clubhouse, and a pool.

One concern was the development’s stormwater retention system. The site’s seven wetlands total 2.51 acres, of which 2.34 acres are regulated by the State of Michigan. To control stormwater discharge into the regulated wetlands, a retention system was originally specified with requirements for excavating a large area and pouring a concrete base slab. However, contractor Concordia Contracting of Sterling Heights, Michigan proposed a design to reduce the system’s footprint and eliminate the need for a concrete base by using precast concrete boxes.

System design and installation

The site’s relatively small footprint wouldn’t allow for a retention pond. As such, the stormwater retention system was placed under a parking lot. Northern Concrete Pipe designed two underground stormwater retention systems using precast concrete boxes to control discharge into the wetlands and accommodate 482 commercial and residential parking spaces. The systems capture water from impervious surfaces during large rain events and detain the stormwater until it can be slowly released into the soils and wetlands.

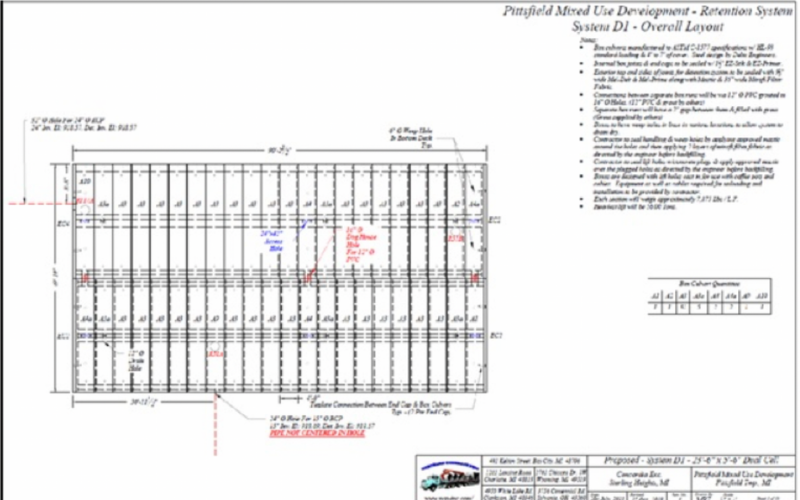

Northern Concrete Pipe designed the layout of the retention systems and manufactured them to ASTM C1577 standards to support loads according to LRFD HL-93.

System 1

The first underground system includes 44 box sections of twin-cell boxes. Each cell has an outside width of 24 feet 10 inches. The system was designed to have two parallel runs of twin cells, set 2 inches apart, with each run comprised of box sections with an 11-foot 5-inch span and 5-foot 6-inch rise. It also has one 24-inch-diameter inlet pipe and one 24-inch-diameter outlet pipe.

During rain events, stormwater fills evenly throughout the entire system before it is released to the outlet control structure. To achieve this, the total system includes six 24- by 42-inch openings in individual boxes to facilitate water flow throughout and provide access for maintenance (and three 24-inch-diameter access holes from the top of the boxes for maintenance). Additionally, nine 12-inch-diameter openings permit incoming water to flow throughout the system. A 6-inch-diameter weep hole is located in the bottom of each of the six boxes to allow infiltration into the soil. The storage capacity is 21,610.85 cubic feet.

System 2

The second system includes 98 sections of twin-cell boxes; each cell has an outside width of 24 feet 10 inches. It was designed to have three parallel runs of twin cells, each set 2 inches apart. Each run is comprised of box sections with an 11-foot 5-inch span and 5-foot 6-inch rise. The system has one 21-inch-diameter reinforced concrete pipe (RCP) inlet, one 12-

inch-diameter RCP inlet, one 4-inch-diameter polyvinyl chloride (PVC) inlet and one 24-inch-diameter outlet.

Rainwater fills evenly throughout the entire system as it releases stormwater to the outlet control structure, made possible by eleven 24- by 42-inch openings in individual boxes that allow waterflow throughout and maintenance (with five 2-inch-diameter access holes located at the top of the boxes for maintenance). Eighteen 12-inch-diameter openings enable incoming water to flow throughout the system. A 6-inch-diameter weep hole is located in the bottom of 22 boxes to allow for infiltration into the soil. The storage capacity is 48,140 cubic feet.

Each box was set on 4 to 6 inches of stone, which eliminated the need to pour a concrete base. With the ability to set 14 box sections per day, the contractor was able to meet the project deadlines and provide a stormwater retention system that will service this area now and in the future.

Construction of the development, including the stormwater retention system, commenced in the spring of 2019. Concordia Contracting installed the smaller of the two systems in five days and the larger system in seven. Easy installation and a steady supply of boxes from Northern Concrete Pipe’s Bay City, Michigan location helped keep the project on schedule and within budget.

Location: Pittsfield Charter Township, MI

Installation Completed: Spring 2019

Project Owner: Beztak Land Co.

Contractor: Concordia Contracting

Precast Supplier: Northern Concrete Pipe Inc.