Concrete Aqueduct Provides a Century of Service

(Civil&StructuralEngineer.com) – A rare structural evaluation performed on a concrete storm water outfall in Salt Lake City recently found that a pipeline constructed in 1910 was still functioning well and was not in need of replacement. The long-term viability of the City Creek Aqueduct was only at issue because of planned construction of a light rail transit line running closely parallel to or above the pipeline.

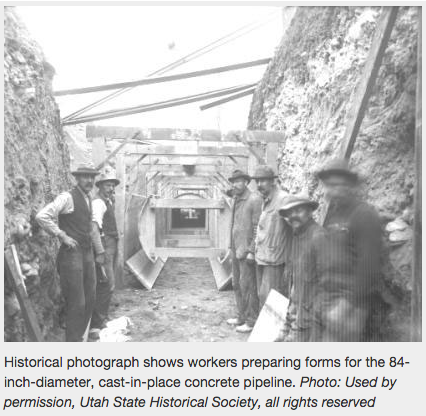

The 84-inch-diameter, cast-in-place concrete pipeline was initially constructed by Davis and Heuser in 1910, which submitted the low bid of $48,252 – roughly $14.50 per foot – for 3,300 feet of 7-inch-thick reinforced concrete. The project included a rushed schedule that required nearly 50 feet of pipeline to be constructed per day. Since precast concrete pipe was not available in that era, the pipeline was cast using an outer frame of round wood staves, with an inner frame of four removable quarter-sections. Historical photographs and newspaper articles showed that excavation and construction was performed with hand laborers and little mechanical help. Yet the contractor was able to work at a record pace, constructing as much as 140 feet of pipeline in a day.

According to a report on Geneva Pipe’s website (www.genevapipe.com/case-studies-details), “Core samples showed compressive strengths of the concrete ranging from 2,830 psi to 5,750 psi. The core samples showed voids in some samples and larger aggregate than would be allowed in concrete mixes today. The reinforcement was a single cage triangular steel reinforcement that had an area of approximately 0.103 square inches/foot (somewhere between a #2 and #3 bar).Ensign Engineering of Salt Lake City was hired to perform a condition assessment, followed by a structural analysis of the 100-year-old pipeline. The study found that portions of the pipeline looked brand new, while other sections had experienced spalling or reinforcing corrosion. Scour from the constant flow of water was also seen in some sections.

While it was difficult to perform a structural analysis because the pipeline conditions varied throughout the length, it can be summarized that both the compressive strength and reinforcement area are less than would be required today. For example, a newly designed concrete pipe of the same diameter would have the same 7-inch wall thickness but steel reinforcing that was nearly four times greater than the original pipeline. Concrete pipe today has a design strength of 4,000 psi, but 28-day compressive strength breaks often reach 8,000 to 9,000 psi, Geneva Pipe said.

Dave Alter, the condition assessment structural engineer from Ensign noted, “This pipe represents an amazing project for its time, but its durability wouldn’t meet today’s standards. The pipe’s stability was mostly based on the soil compaction around the pipe. Based on the performance of the original pipe, concrete pipe with today’s design and quality control should easily last 100 years.”

“As part of the light rail project, precast reinforced concrete pipe of the same size was used to the replace original pipeline,” Geneva Pipe reported. “Other sections of the pipeline that are less affected by the light rail line will be left in place and with more frequent condition assessments planned for the future.”

Today, the U.S. Army Corp of Engineers recommends a design life of 70 to100 years for precast concrete pipe. The City Creek Aqueduct in Salt Lake City is just one of countless examples of installations that surpass those service-life numbers.

This article was provided by the American Concrete Pipe Association, with additional details from Geneva Pipe’s website.